BALL VALVES DIVISION

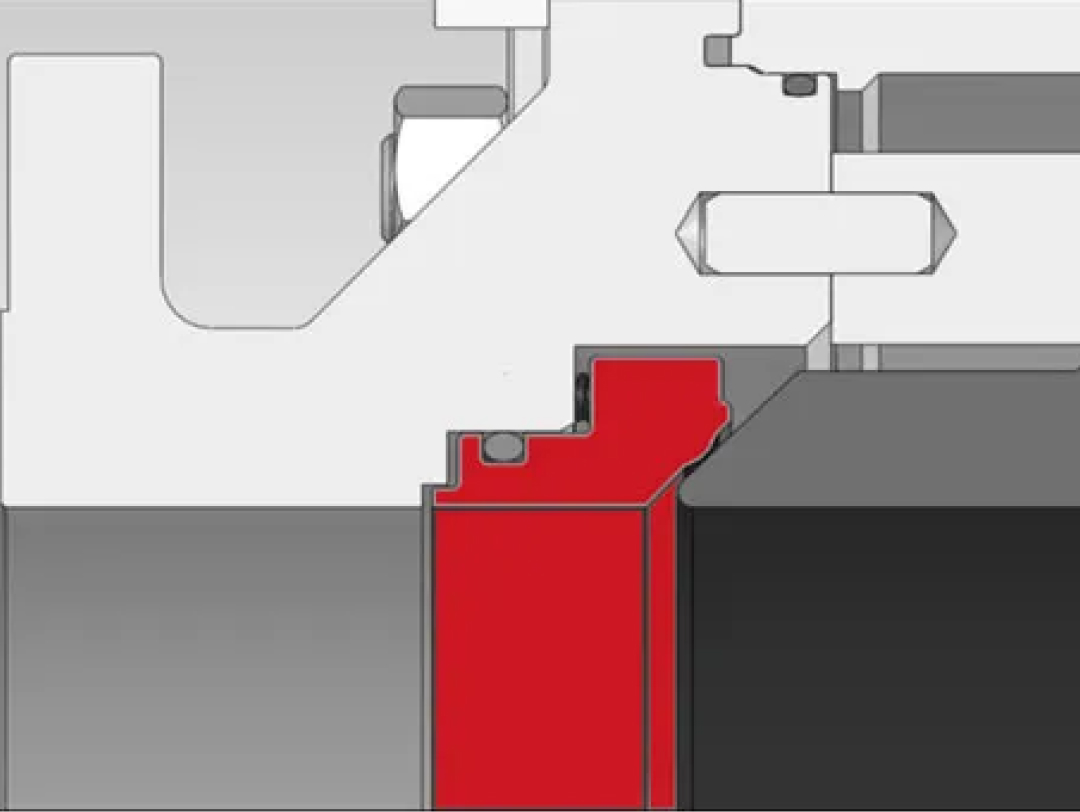

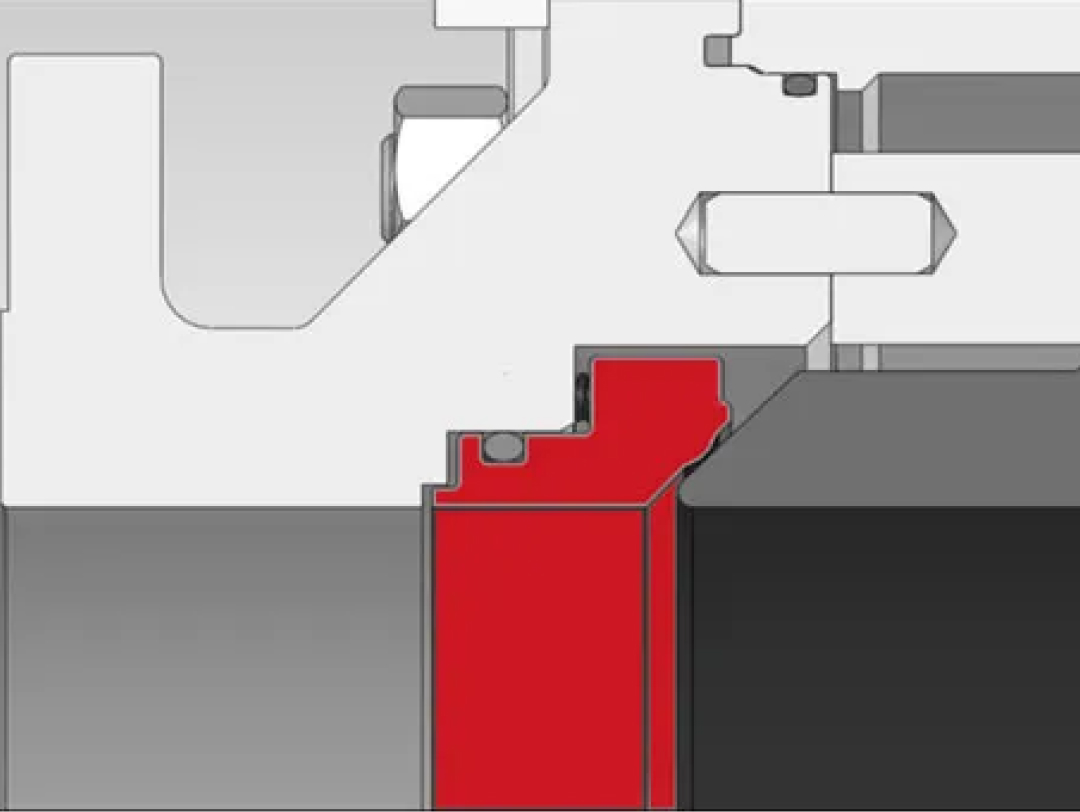

Tormene Trunnion Mounted Ball Valves are the ideal solution for tight shutoff requirements in pipeline applications such as line closure, tie-ins, maintenance isolation and more. The control of the flow is done by a perforated pivoting ball supported by trunnions or bearing retainers. Sealing is performed by floating seats under the action of the line pressure itself, allowing the valve to be fully bidirectional. The valves feature a side entry split body geometry in 2 or 3 pieces, both form cast and forged materials. The trunnion mounted design allows a direct transfer of the pressure load acting on the closure member to the valve body. In this way, stresses on the stem are minimized, service lifetime of the seals is extended, leakage towards environment prevented and torque requirements reduced. The bolted body design allows an easy on-site inspection, maintenance, and replacement of the internal parts.

| APPLICABILITY | STANDARD/CODE |

|---|---|

| Valve design | API 6D |

| Pressure rating, Pressure containing parts (if required) | ASME B16.34 |

| Face-to-face | ASME B16.10 |

| Pressure containing parts and bolting design | ASME VIII-1 / 2 or EN 12516 |

| Flange design (up to DN 24’’ and up to 48”) | ASME B16.5 / B16.47 |

| Buttwelding ends design | ASME B16.25 |

| Part turn actuator attachments | ISO 5211 |

| Fire Test for Valves | API 6FA/API 607 |

| Materials for sour service | ISO 15156-1/NACE MR0175 |

| Seat leakage rate | ISO 5208/API 598 |

| Fugitive Emission Factory Test | 20 |

In-line Sealing

All API 6D seating configurations are available. Two single piston effect seats are provided as standard with Double Block & Bleed feature. Double Isolations and Bleed configurations (DIB-1 and DIB-2) are available upon request.

As a standard, valves are provided with a thermoplastic sealing surface which ensures perfect tightness as per API 6D (Rate A, ISO 5208). A wide material selection (rPTFE, Devlon, Peek, PCTFE, etc) is available to optimize the performances of sealing, torque, wear, mechanical, chemical and thermal resistance for the specific application.

Metal-to-metal valves are available and recommended for critical applications when wear, high temperature, dirty fluids are present